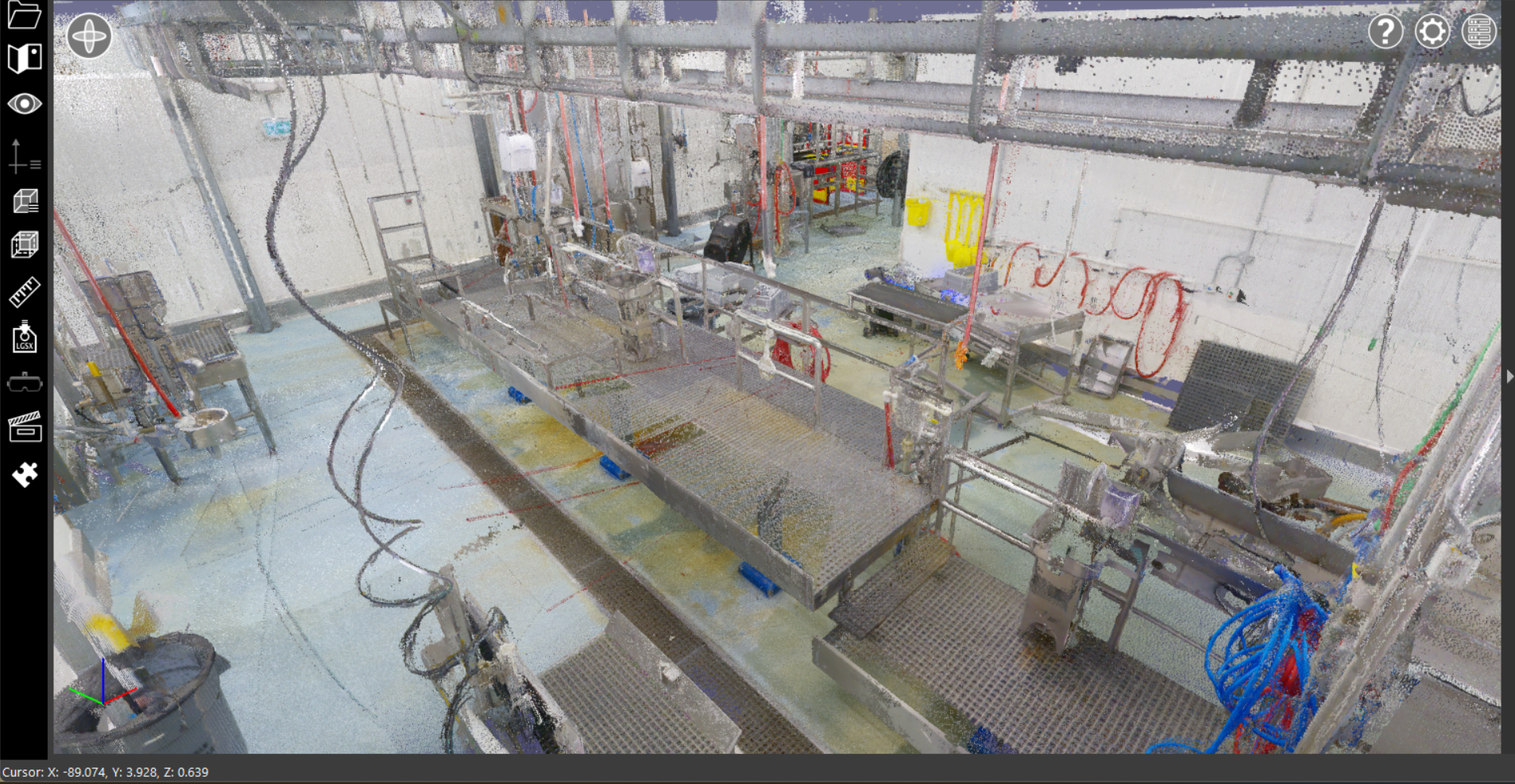

Construction presents a unique challenge in today’s world, with increasing complexity and higher construction costs. So, what is the solution? How can we become more proactive in preventing issues and delays on job sites? The solution is setting up your project for success by utilizing the latest tools and techniques available to eliminate this pain. One of the tools we use is Leica 3D scanning, which creates a highly accurate point cloud that allows you to see your entire building in virtual reality. That 3D map can then be converted into your BIM model, like Revit, which the design team can use to create your construction drawings.